Chile's State-run copper miner Codelco must focus on boosting its production, but it has a global prestige that would not be tarnished if it cedes its role as Chile's top producer to rival BHP, Mining Minister Aurora Williams said on Thursday....

Latest

Most Read

Receive our free daily newsletter:

Sponsored Posts

Latest News

A video round up of this week’s magazine, highlighting our cover story, features and Business Leader.

Multinational mining and metals processing company Sibanye-Stillwater says the Siphumelele shaft at its Rustenburg operation is on schedule to resume production during May, as planned. A surface...

Steadily improving milling rates enabled ASX-listed Tietto Minerals to reach record quarterly production of 37 111 oz of gold from its Abujar mine, in Côte d'Ivoire, for the quarter ended March 31....

London-listed mining services company Capital has recorded a 3.1% year-on-year increase in revenue to $80.2-million for the quarter ended March 31, marking a good start to its financial year....

LSE- and TSX-listed gold miner Centamin reports that the scheduled processing of lower-grade ore from the Sukari openpit, alongside the planned underground ventilation upgrades and mill maintenance...

South Africa will use future drawdowns of its Gold and Foreign Exchange Contingency Reserve Account to curb its debt burden, Finance Minister Enoch Godongwana said, adding he was pondering tax...

ASX-listed Challenger Gold has placed an additional A$4-million to a single investor at 8.5c a share for an one-for-one option exercisable at 14c a share. The investor approached the company and...

Sponsored Posts

Latest News

ASX-listed Spartan Resources on Thursday unveiled an A$80-million fully underwritten equity raising to accelerate exploration and development of the Dalgaranga gold project, in the Murchison...

Toronto-listed Solaris Resources and the Shuar communities of Warints and Yawi have signed an updated impact and benefits agreement (IBA), reflecting the evolving growth and development of the...

Police have named Air Canada employees among the suspects in the theft of 6 600 gold bars from a cargo facility at the country’s busiest airport, in what’s been dubbed Canada’s largest-ever gold...

Aim- and ASX-listed Jubilee Metals has achieved record production levels at its South African chrome operations, both on monthly output for March and for the quarter ended March 31 – which is the...

JSE- and ASX-listed Orion Minerals has requested an immediate trading halt to be placed on its securities, pending the release of an announcement in relation to exploration results at its Okiep...

New silver explorer and developer Silver Sun on Thursday announced the opening of an initial public offering (IPO) on the Australian bourse, bringing to market its silver and gold project in...

Australia’s wealthiest woman, Gina Rinehart, continues to bolster her global mining footprint with a strategic investment in a copper and gold project in Ecuador. Hancock Prospecting has entered...

Sponsored Posts

Latest News

Diversified mining company BHP is nearing a decision regarding its nickel operations in Western Australia. The company, which has been conducting a review of these assets since February, is...

Chile's struggling state-owned copper giant Codelco will be able to diversify its business, improve cash flow and change its business profile with its entry into the lithium market, Moody's said on...

Canada's federal budget on Tuesday unveiled few emissions-cutting policies, but climate advocates say the key for Justin Trudeau's Liberal government is to prioritise implementation of existing...

Aurubis, Europe's largest copper producer, plans to eschew large acquisitions and instead build a network of recycling facilities across the globe as part of its focus on organic growth, its CEO...

Australian oil and gas producer Santos said on Thursday its first-quarter revenue fell about 14%, hurt by lower production across its product portfolio and a decline in volumes in recent months....

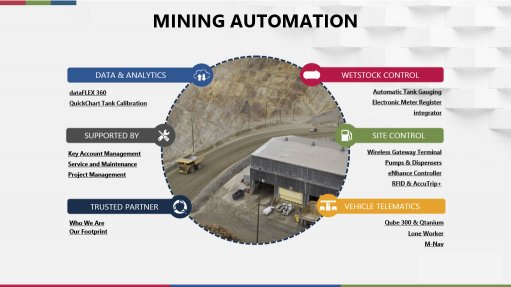

African technology innovator Sedna Industrial IT Solutions has partnered with video networking and visual collaboration solutions provider Haivision to bring industrial and mining command control...

Standard Bank head of Southern Africa’s oil and gas coverage Paul Eardley-Taylor has suggested that South Africa needs 13 GW of gas-to-power (GtP) capacity, rather than the 7.2 GW to 8.6 GW...

A video round up of this week’s magazine, highlighting our cover story, features and Business Leader.

Rwandan President Paul Kagame and First Lady Jeanette Kagame, preparing to light the Rwandan genocide flame of hope, known as the ‘Kwibuka’ (Remembering), to commemorate the 1994 Genocide at the...

- Engineering News Features

- Automation & Industry 4.0

- Electric Power Generation & Transmission

- Vessels, Heat Exchangers, Tanks & Containers

- Mining Weekly Features

- Drilling & Tunnelling

- Tailings & Waste Management

The disbanded South African mining industry’s research and development (R&D) arm Comro handed South Africa’s State-owned Council for Scientific and Industrial Research (CSIR) the mining R&D it had...

The recent period of decreased loadshedding has been met with tremendous scepticism by a South African public who have been burnt more times over the past 15-plus years than a lump of wet coal....

Business Leader

This we profile Rhian Capostagno, a partner at Partners in Performance, a firm of management consultants

The storms that lashed the Cape earlier this month caused devastating damage, with many still picking up the pieces. One can only hope that the coming election storm is far more benign, but some of...

Popular This Week

Latest Multimedia

Research Reports

Projects

Showroom

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation